Main characteristics and applications

Threading rolls and dies, cold extrusion tools, trimming, cutting and stamping tools for sheet thicknesses up to 6 mm, precision cutting tools for sheet

thicknesses up to 12 mm, cold pilger mandrels, circular-shear blades, deep-drawing tools, pressure pads and highly wear-resistant plastic moulds.

Comparable standards

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|

| X155CrVMo12-1 | 1.2379 | Z160CDV12 | D-2 | SKD11 |

|

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr | Mo | V |

|---|

| 1.45-1.60 | 0.10-0.60 | 0.20-0.60 | 0.03 | 0.03 | 11.0-13.0 | 0.70-1.00 | 0.70-1.00 |

|

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | | Coefficient of thermal expansion at °C 10-6 m/(W/mk) | 10.5 | 11.5 | 11.9 | 12.2 |

|---|

| Thermal conductivity at °C (W/mk) | 16.7 | 20.5 | 24.2 | - |

|---|

Steel properties

12 % ledeburitic chromium steel. Combines maximum wear resistance, good toughness, outstanding cutting edge retention and tempering resistance.

It can be nitrided after special heat treatment.

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | HARDNESS |

|---|

| Annealing | Heat to 830 – 860 °C | Min. H.T. for 2 minute /mm | Furnace | - |

|---|

| Stress relieving | Heat to 650 – 700 °C | Min. H.T. for 2 minute /mm | furnace | - |

|---|

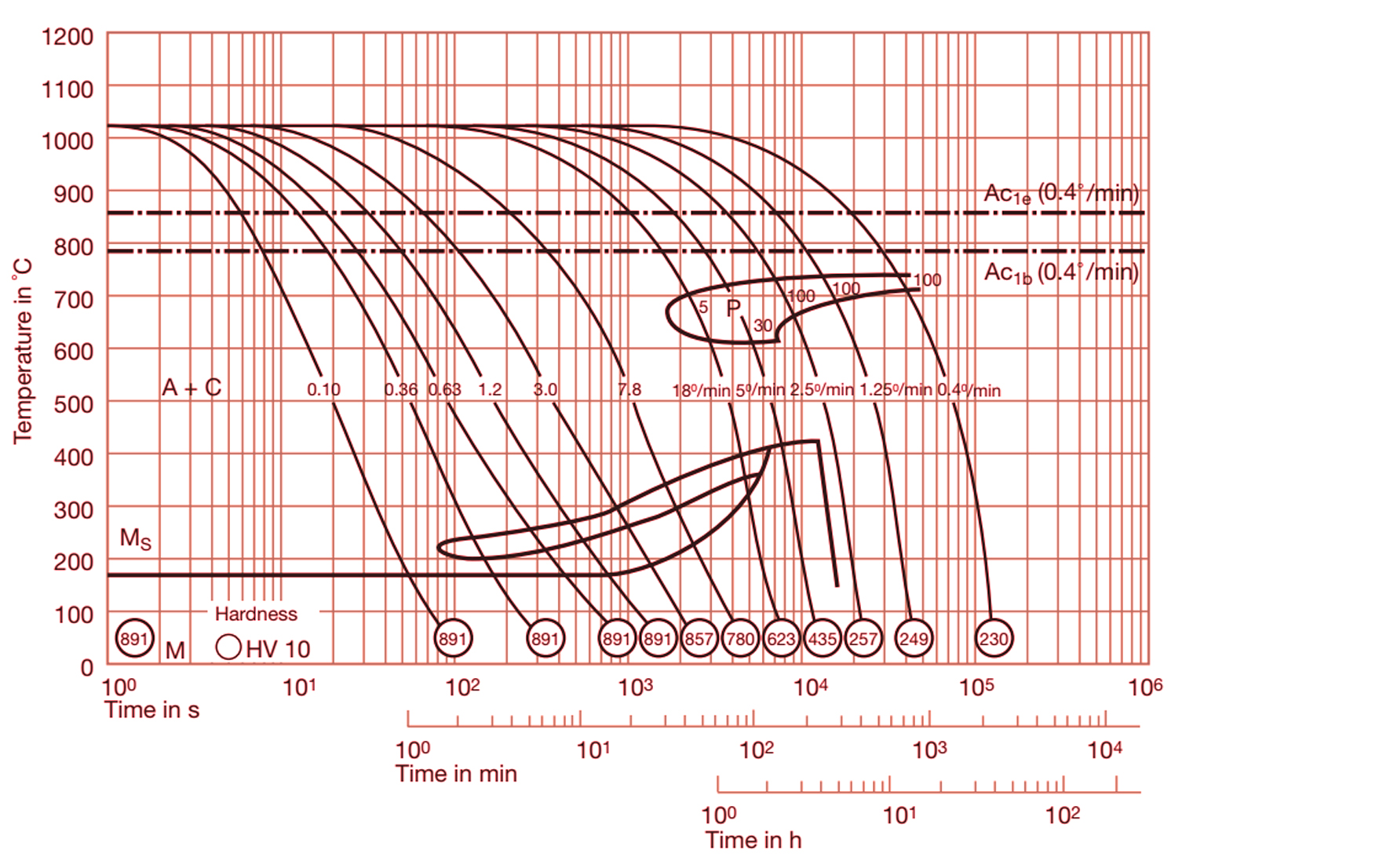

| Hardening | Heat to 1000 – 1050 °C | Min. H.T. for 1 minute /mm | Air, oil or saltbath, 500 – 550 °C | - |

|---|

Note

Hardening temperature 1050-1080 °C, tempered 3 times

Hardening temperature 1050-1080 °C, tempered 3 times

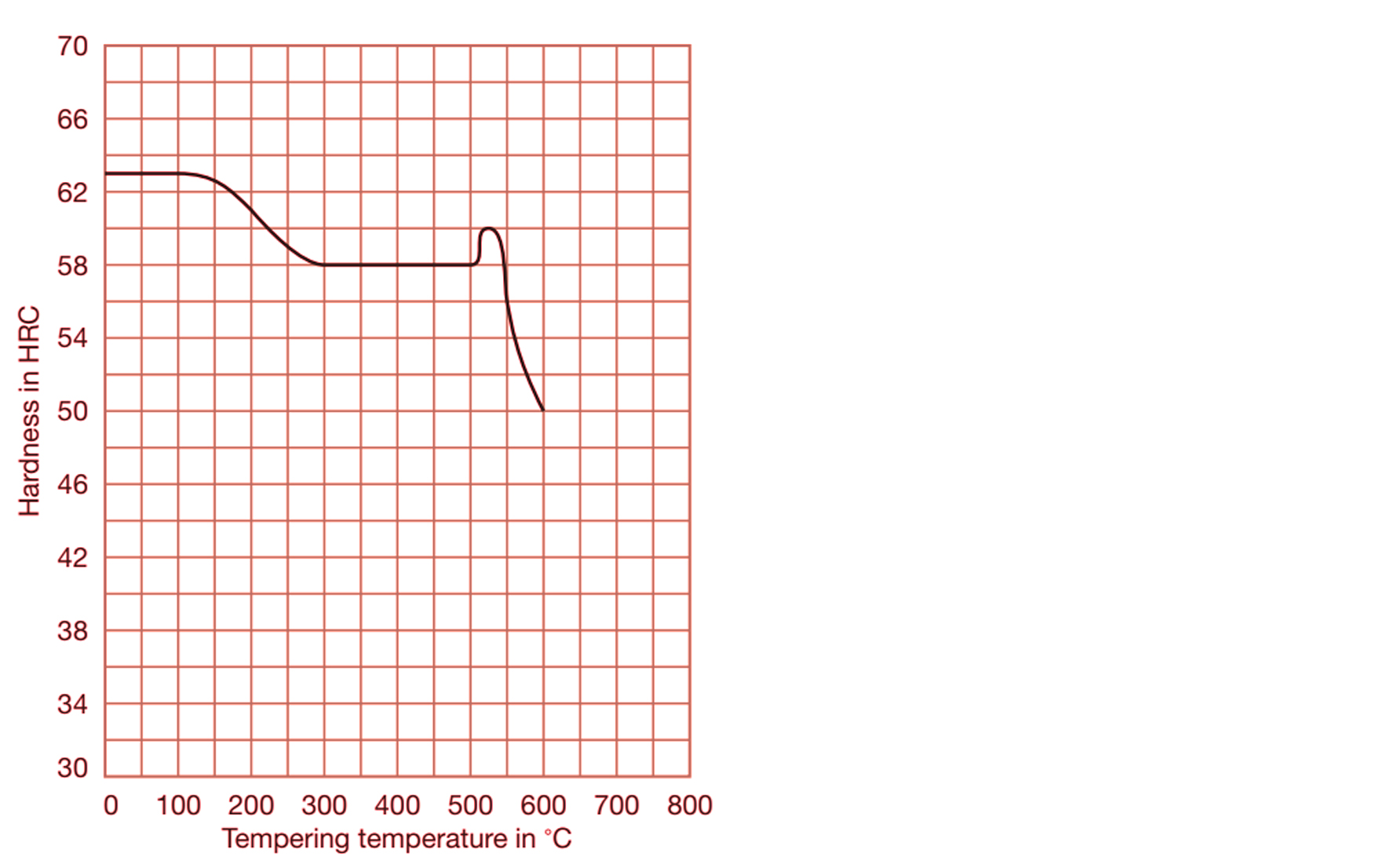

Chart of tempering values depending on the hardness

| °C | 100 | 200 | 300 | 400 | 500 | 525 | 550 | 600 |

|---|

| HRC | 63 | 61 | 58 | 58 | 58 | 60 | 56 | 50 |

|---|

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to

great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc.

The range of Tool Steel in our store includes products from renowned manufacturers.