W.NR. 1.2329

Main characteristics and applications

Hot-work tool steel for forging dies, pressure disks for extrusion, mould press dies, and many other applications.

Comparable standards

| UNI | W.Nr | DIN | AFNOR | AISI/SAE | BS |

|---|---|---|---|---|---|

| - | W.NR. 1.2329 | 46CrSiMoV7 | - | - | - |

Chemical composition (typical; in weight %)

| C | Si | Mn | Cr | Mo | Ni | V |

|---|---|---|---|---|---|---|

| 0.45 | 0.70 | 0.80 | 1.80 | 0.30 | 0.60 | 0.20 |

Steel properties

Excellent tempering resistance, high-temperature strength, full quenching and tempering properties, outstanding weldability, nitridable, PVD and CVD coatable, good machinability.

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | HARDNESS | |

|---|---|---|---|---|---|

| Annealing | Heat to 780 – 800 °C | Min. H.T. for 2 minute /mm | Furnace or air | max. 230 | |

| Hardening | Heat to 880 – 920 °C | Min. H.T. for 1 minute /mm | Air, oil or hot bath, 200 – 250 °C | 53 – 55 | |

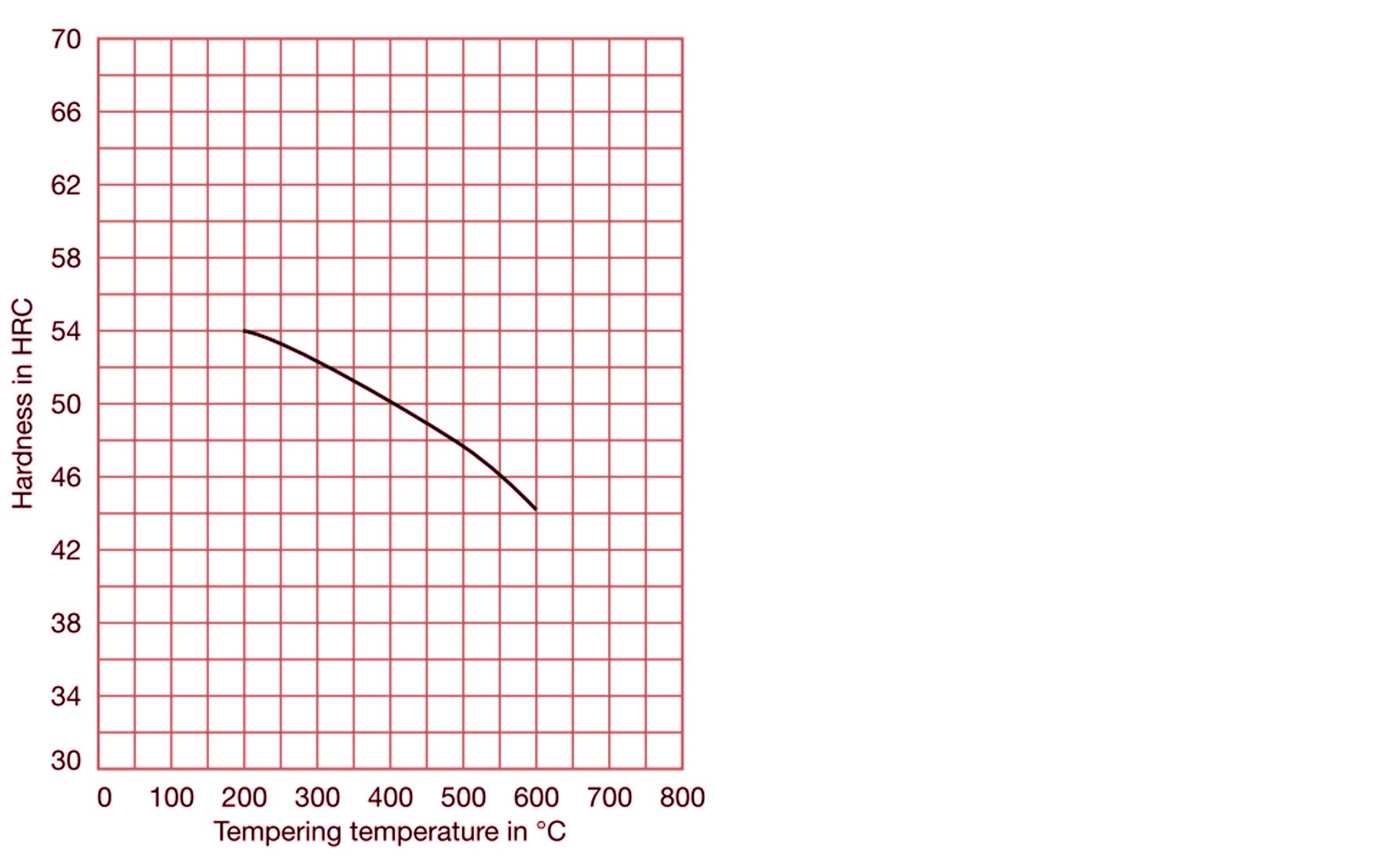

Tempering diagram

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.